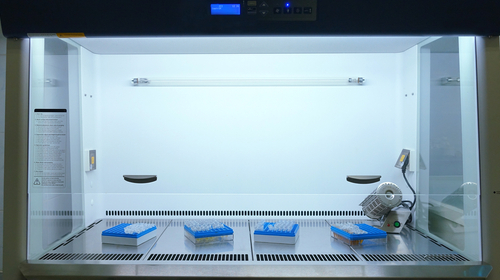

When undergoing specific industrial and experimental processes, you may require a laminar flow cabinet to carefully control your environment. These are often used in conjunction with a specialised cleanroom or controlled environment to ensure the air in the space remains constant for particular uses.

What is a Laminar Flow Cabinet?

A laminar flow cabinet is an enclosed cabinet equipped with a HEPA (high-efficiency particulate air) filtered airflow system. It’s used to create an aseptic environment to undertake different experiments that require a space that’s free from contamination. This is often used for biological or particle-sensitive materials that are worked within laboratories.

Laminar flow cabinets circulate airflow in one direction, in a completely consistent stream. This is required to create airspace with little or no turbulence, at a constant velocity around 0.3-0.5 m/s.

How Does it Work?

Laminar Flow Cabinets work by blowing smooth slows of air away from the sample or protected material and towards the user. Laminar airflow is used to ensure no unfiltered particles are moving without control in turbulent airflow. As the laminar air is HEPA filtered, chances of the sample becoming contaminated are significantly reduced.

A high quality of specialised airflow is required to carry unwanted particles to be filtered, so creating this flow is essential.

What is HEPA filtration and why is it needed?

HEPA stands for high efficiency particulate air. This type of filtration is used for contamination control, to keep the air in an enclosed space free of specific impurities.

A HEPA filter contains a mat composed of randomly arrayed fibreglass, around 0.5 to 2.0 micrometres thick. As the air travels through the filter, the pollutant particulates and contaminants are trapped by the fibres, meaning the air that passes through to the end is cleansed and aseptic for cleanroom use. This is an essential component for the laminar flow cabinets’ function.

What is Laminar Flow?

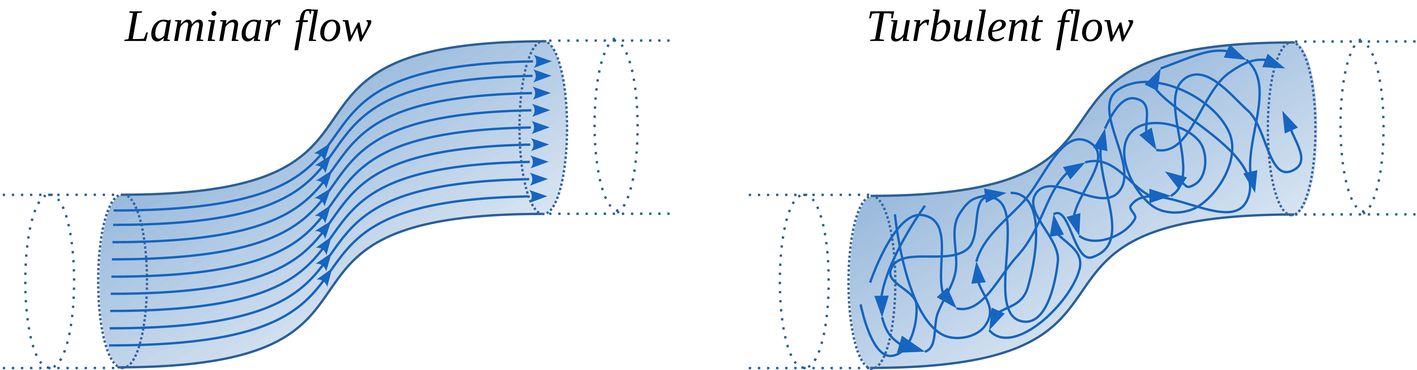

A laminar, or unidirectional flow, is an airflow in which the entire body of air within a space is moving constantly in one direction at a consistent speed and pressure. Air flow is controlled by a single filter which pushes the air through the space horizontally or vertically. It prevents airborne pollutants from entering the room.

A clean room should have at least 80% of its ceiling covered with an airflow system. Non-directional materials such as air flow filters are used to evenly distribute the air.

Unidirectional air flow filters are widely used in cleanrooms to remove particulate matter from the air. These components are ideal for minimizing air pollutants.

Laminar vs. Turbulent Flow

In contrast to laminar air flow, turbulent air flow encourages turbulence by creating unintentional clashes of air flows that deposit particles at random on surfaces within enclosures.

When obstructions are present inside enclosures, their turbulence can be problematic for work that requires a dust-free environment and can lead to contamination. Rubbermaid containers, for instance, can create this unwanted turbulence.

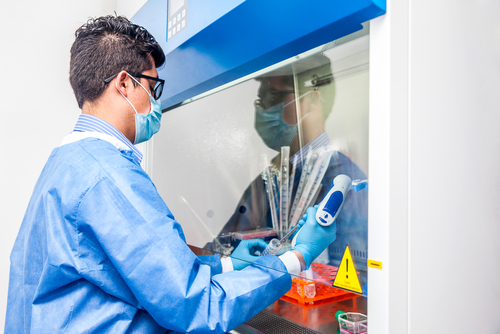

What is a laminar flow hood?

Clean bench and biological safety cabinet examples are commonly used as examples of Laminar flow hoods. These units are designed to direct high-quality air into the work surface.

The concept of laminar air flow, which is also known as homogenization, was first introduced during the 1960s. It’s a vital part of modern laboratory equipment that helps keep the air moving safely.

Horizontal and Vertical Laminar Flow

Laminar flow enclosures can be either vertical or horizontal configurations. Both have their own benefits for cleanroom work.

In order to minimize air turbulence on the work surface, horizontal laminar flow hoods are best used when working with typically small utensils and equipment that will not interrupt the airflow.

Hands and gloves are positioned downstream of the sample when using horizontal flow, which offers the best contamination protection.

The horizontal laminar flow hood is the best choice for applications that require large equipment on the worksurface as it allows for a larger workspace and produces less turbulence as the air is flown vertically. The similarity of vertical laminar flow hoods to cleanrooms makes them a popular choice for many applications. With the help of gravity and an airflow which moves downward, it is possible to push particles towards the ground and away from the operator’s work station.

How do I know when to choose a vertical laminar flow cabinet?

Vertical laminar flow cabinets provide a more spacious, deeper work area when using larger equipment. Due to the fact that the air that is expelled from the work area goes back into the environment untreated, it is only recommended that non-hazardous materials are handled in the area.

How pressure gradients control contaminant flow

When your work requires carefully controlled air, pressure should be a priority. Air conditioning should be used to achieve specific levels of air pressure in your cleanroom or working space.

Pressure differences naturally influence airflow. In case a door between adjacent spaces is opened, for instance, you can ensure that air will always flow in the desired direction because of the pressure difference. Whenever contaminants are in the air, they always move in the same direction as the current; creating a gradient in pressure means only the contaminants will move in the direction you want.

Pressure can be adjusted in a controlled environment by pumping more air into the space than you remove. This can be controlled with a high level of precision and can be easily altered if different pressure conditions are required at different times.

Want to know more about Controlled Air Conditioning?

At Total Environmental Kooling (TEK), we specialise in providing, installing, and maintaining specialised air conditioning systems. We also provide cleanroom installation and close control room installations for specific processes.

With many years’ experience in the air conditioning and ventilation industries, and the offering of bespoke close control and cleanrooms, Total Environmental Kooling provides a professional design and installation service to domestic, commercial, industrial, public and private sector customers in Bristol and throughout the UK.

Total Environmental Kooling is an approved installer for Daikin, Mitsubishi, Stulz, ICS, Trox, Denco, Toshiba, Panasonic and LG with experience with many other manufacturers too.