What is a cleanroom?

Cleanrooms are used across a wide variety of industries and are designed to prevent the particles of dust that are usually present in every indoor environment from potentially damaging delicate manufacturing processes. Often used in manufacturing or scientific research, cleanrooms are designed to maintain extremely low levels of particulates, such as dust, airborne organisms, or vaporised particles.

How different industries use cleanrooms

Cleanrooms provide controlled environments which are a necessity in many industries. These types of sterile environments can be found in the Automotive, Microelectronic, Nanotech and Medical industries amongst others, and are vital for the successful processing and manufacturing of a wealth of component and medical solutions.

- Aerospace: Within the aerospace industry a cleanroom environment is required to create many aerospace tools so that there are no contaminants of pollutants present which could compromise the tools used in the manufacturing process of the product which is being manufactured.

- Optics: We use cameras every day and often need to wipe down the lens if a picture is a little blurry, it would be pretty inconvenient if the dust was on the inside not the outside! That’s why clean rooms are so important in the manufacturing of lenses to stop particle contamination, as well as control he humidity and temperature – for optimum lens production!

- Nanotechnology: In the field of nanotechnologies there is a need for extremely clean environments completely free of gases, particles, and any other contaminants which can be present. These can impact product quality if present during the manufacturing process.

- Universities: Research labs at universities need to be able to have the strictest control over the conditions as unaccounted for particles can throw the experiments and results off. Accuracy is highly important for ab research so all variables that could affect the experiment must be removed creating a contaminant-free environment.

- Biological Safety: In environments where scientists are working with biological substances that could be dangerous, it’s imperative to keep the substances from getting outside. It’s also highly important that the interior equipment protects the scientists while they conduct their procedures.

What Does A Clean Room Look Like?

This kind of contaminate-free area can vary in size depending on the type of premises they are required for. They should all have a similar layout though, that would comprise of:

A Gowning Area or Ante Room

A Gowning Area or Ante Room is a specialist area is where all trained personnel will put on dedicated cleanroom clothing like smocks, jackets, face masks, gloves and shoe covers before stepping inside the main area of the cleanroom. Different manufacturing processes require different levels of protective clothing to be worn, and anyone who enters will always need to be appropriately dressed.

The Process Area or Buffer Room

The Process Area or Buffer Room is where the product is prepared or constructed, and usually has a higher level of contamination control than the ante room. Visitors to this area will immediately feel the increased pressurisation of the room the second they walk into it. There will also be restrictions in place on the equipment, tools and other controlled products that can be transferred in and out.

The Critical Process Area

This area will have the highest level of contamination control in the whole building, and will also be subject to a higher level of filtration or air pressure than other areas. Used for the manufacture of the most sensitive components and processes, only specialist staff will be allowed to enter.

Modular Cleanrooms

Modular cleanrooms are freestanding structures, which are modular, designed as a more affordable solution while still being able to provide precision-controlled environments. Modular cleanrooms also allow different environmental conditions across different areas, when that’s required for your business’s operational needs.

Types of cleanrooms

There are various types of cleanroom options. Depending on your needs and requirements, will negate the best cleanroom solution for you. The types of cleanrooms you may choose between are:

Hardwall cleanrooms

Hardwall cleanrooms can be split up, into zones with individual controls if needed.

Softwall cleanrooms

Softwall cleanrooms are an economic solution for your cleanroom needs. They’re often favoured so short-term and temporary arrangements.

Laminar flow cabinets

Laminar flow cabinets are used to allow fluid flow in one direction with no interruption from turbulence. The clean air resultantly has a unidirectional down flow which ensures that only extremely clean air will pass over the process.

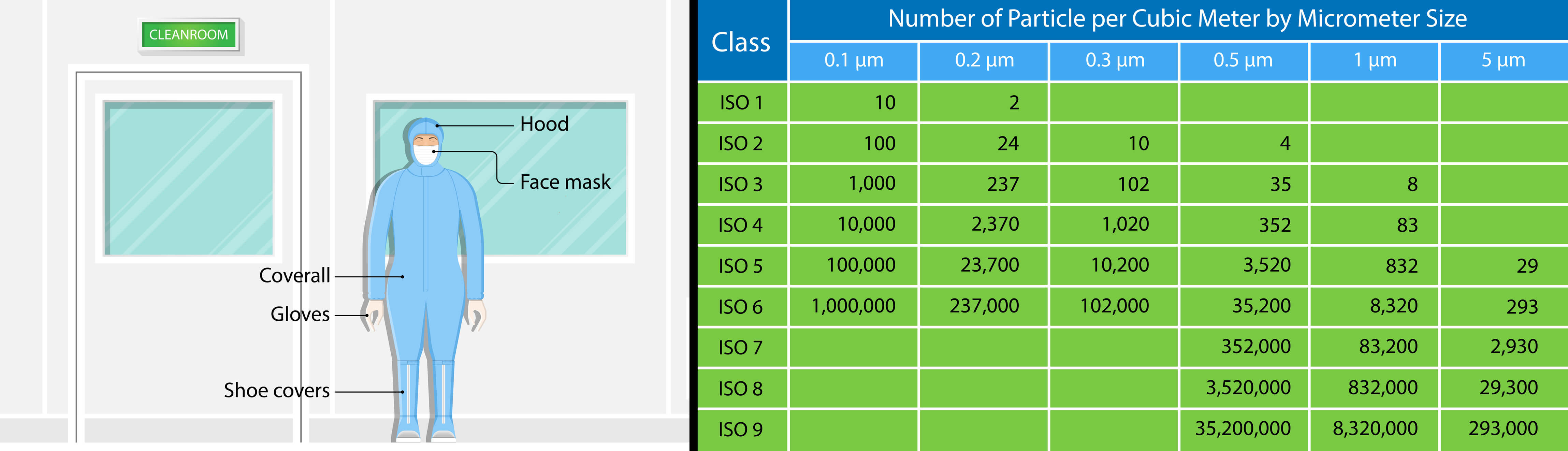

Cleanroom standards/classes (ISO, EU GMP, US, British)

The classes of cleanrooms are graded by how clean the air is. So, they classification of cleanroom you will require will be dependent on your needs. Clean rooms are ranked according to the number and size of particles permitted by unit of volume of air.

This basically means that large numbers such a ‘class 100’ or class ‘2000’ refer to FED_STD-209E, which denotes the quantity of particles that are equal to or larger than 0.5 µm.

Standard room air is usually around 1,000,000 or ISO 9.

Temperature Controls And Working Environment

Temperature controls in your working environment can need to be controlled for a variety of reasons. Be it for the comfort of your personnel, precision measuring equipment or the compounds and ingredients you work with. By using a cleanroom, you can be sure to have complete, precise control over your working environments.

Because the work undertaken in the cleanroom is vital to the manufacturing or development processes across a range of industries, the working conditions need to comfortable enough for staff to be able to concentrate and work unimpeded for long periods of time.

These facilities, therefore, usually provide a comfortable and well-lit working environment, which typically includes a temperature of 20° or cooler, to maintain comfortable conditions for all personnel.

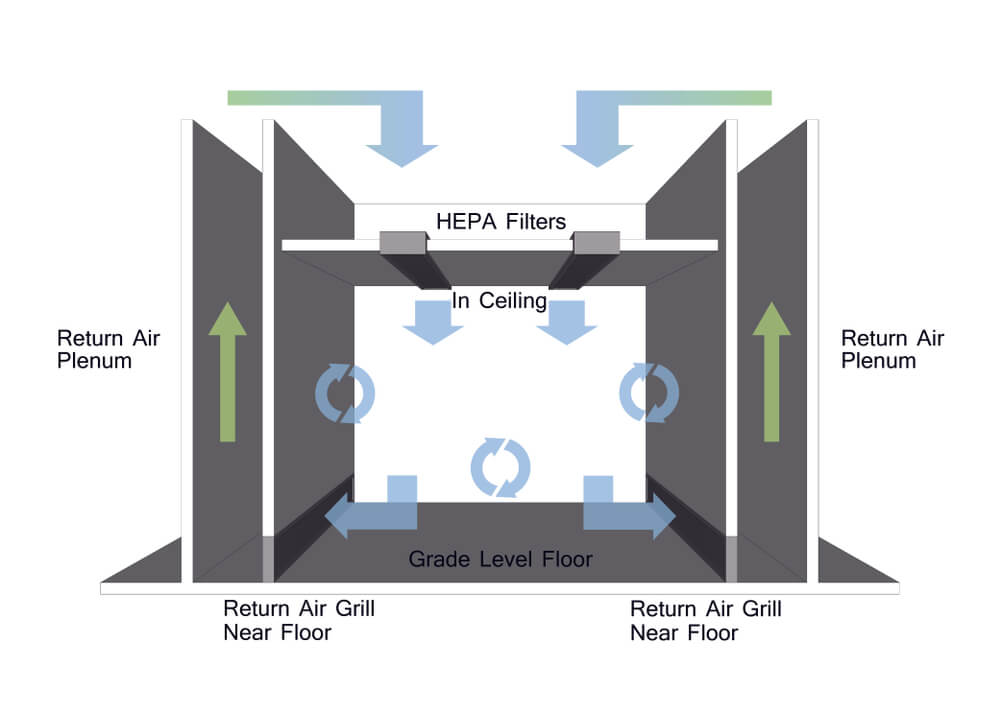

Air Quality and Filtration

Highly efficient filters to dilute and remove particles are the most important part of any clean room environment. Using either HEPA or ULPA filters, dust particles, bacteria and chemicals are circulated away from the room. The air is also used to pressurise the room and to ensure that no contaminated air flows back into the cleanroom environment.

Cleanroom airflow practices

Airflow in the most important fundamental component of cleanrooms. The airflow must be designed to stop contamination and microorganisms in the airstream. This means that when your cleanroom is being designed the utmost attention has to be paid to the factors that will affect air filtration, air velocity and airflow.

Unidirectional flow is an airflow that moves in a single direction in a robust and uniform manner. The air flows at a sufficient speed to sweep particles away from the critical areas of the cleanroom. The purpose of the unidirectional airflow is to push outward the contaminants which could otherwise be deposited into the air stream, stopping the potential for contamination which could otherwise drop out of the air-stream.

Personnel Contamination of Cleanrooms

Humans are considered to be the biggest threat to the environments in cleanrooms. Your personnel can account for 75-80% of particles and microbes which can be present in a room. To limit this, your employees should be well trained in procedures which can avoid potential contamination sources from their actions. Your gowning protocols should be established in order to avoid limit personnel contamination most effectively.

Cleanroom Installation Service from TEK

To create a perfect cleanroom environment, it needs to use a variety of the latest technologies depending on the individual business needs. Total Environmental Kooling provides the best Cleanroom installation services in Bristol and the South West, as we work with cutting-edge technology to provide effective and affordable cleanroom solutions.

If you need a cleanroom installation, get in touch with us and we’ll discuss your requirements. We’ll need you to provide the full details of your needs so we can work together to find the solution to control the particulate size and levels suitable for the optimum environment for your business.

For more information, you can call us on 0117 952 3355 or you can contact us online and we will get back to you.