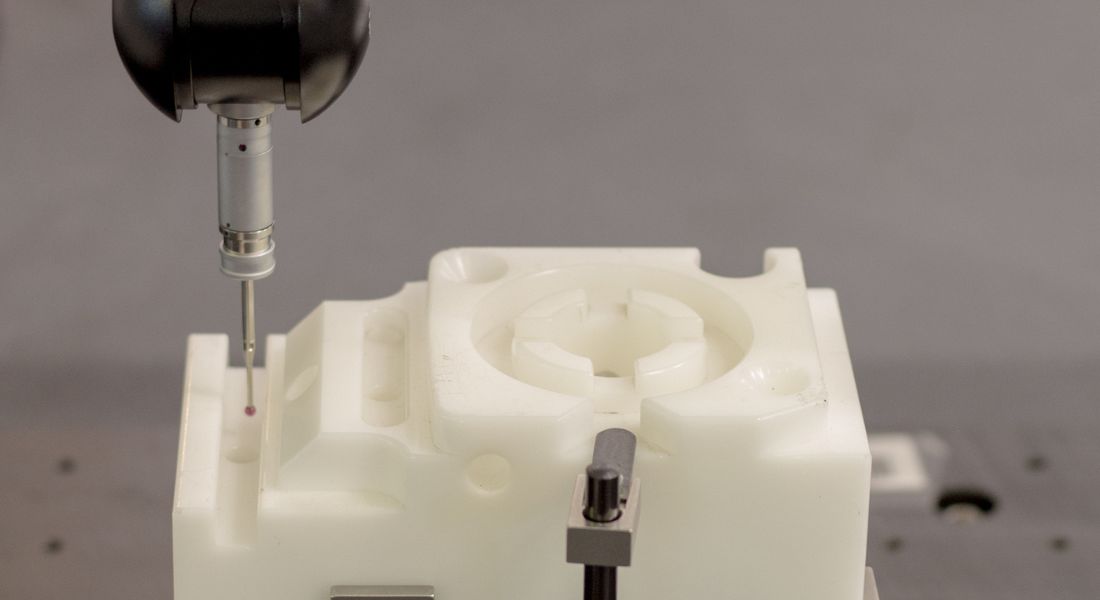

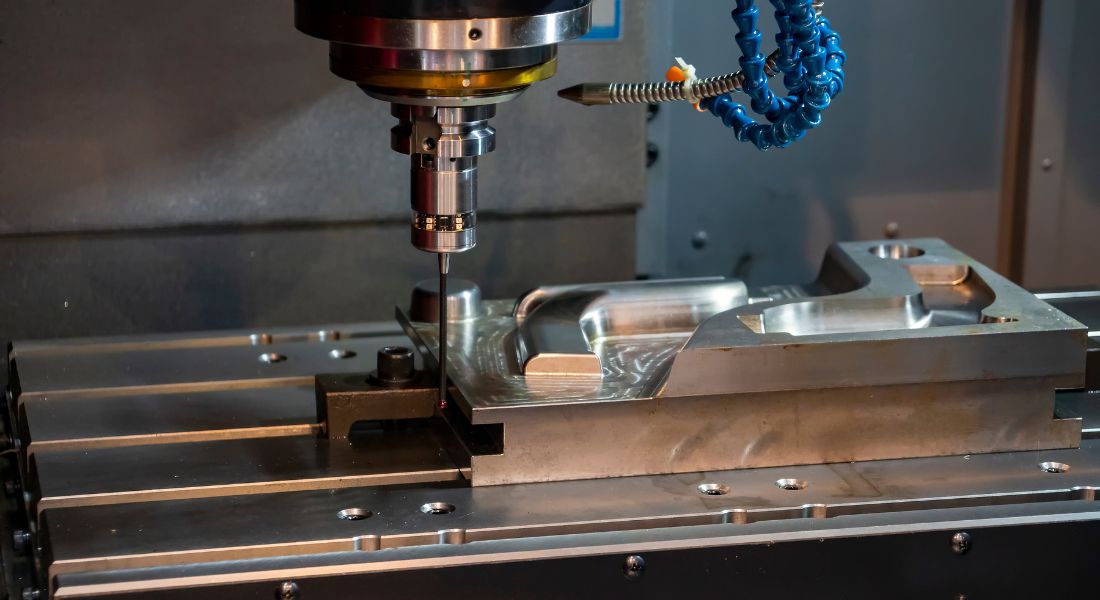

In the world of manufacturing and quality control, having accurate measurements is crucial. That’s where Coordinate Measuring Machines (CMMs) come in. A CMM room is a specialised space that houses these machines, allowing for precise measurements and quality control of manufactured parts and products.

In this article, we will delve into the world of CMM rooms, exploring what they are, the benefits they provide, and how they can benefit your business.

A CMM Room – What does it Mean?

Coordinate measuring machines (CMMs) are housed in dedicated, temperature-controlled environments known as CMM rooms . By precisely measuring the physical dimensions of manufacturing products and components using cutting-edge technology, these devices make sure they adhere to the required requirements and tolerances.

The limited temperature and humidity variations, the minimal vibration, and the minimal electrical interference are all features of CMM rooms. This is necessary to guarantee the precision and consistency of the measurements made by the CMMs.

Increasingly sophisticated and accurate CMM machines require tighter atmospheric control within the environments in which they operate. CMM Rooms and enclosures are therefore becoming increasingly critical in ensuring that the capabilities of the CMM machines are achieved, with latest CMM machines also shutting down if the environment is not adequate.

In a production facility, the CMM room is normally a distinct, enclosed area with a specialised climate control and filtration system to maintain a constant temperature and hygienic environment. The room’s floor, walls, and ceiling have all been constructed to reduce vibrations and electrical interference. There may also be soak areas or air locks depending on the products or machine requirements.

What are the Benefits of Using a CMM Room?

A CMM room provides a number of benefits for manufacturers and businesses.

These include:

- Precise measurements: The controlled environment of a CMM room ensures accurate and repeatable measurements, allowing for better quality control of manufactured parts and products.

- Improved efficiency: By housing CMMs in a dedicated, temperature-controlled

environment, manufacturers can improve the efficiency of their quality control processes. This can reduce the need for multiple measurements and rework, saving time and money.

- With the right operating environment you can maximise the usage and productivity of the CMM machine as it will have the correct temperature and humidity in which to operate.

- Enhanced product quality: Accurate measurements and quality control lead to improved product quality, which can help to increase customer satisfaction and loyalty.

- Increased competitiveness: By providing a controlled environment for quality control, businesses can demonstrate their commitment to providing high-quality products and services. This can help to increase competitiveness and win new business.

How Can a CMM Room Benefit Your Business?

A CMM room can be the answer you’re seeking for if you want to raise productivity, enhance product quality, and increase your competitive advantage. A CMM room could help your company in the following ways:

- Increased precision: The accurate measurements offered by CMMs in a controlled setting will assist you in identifying and resolving any problems with your production processes, improving accuracy and product quality.

- Enhanced productivity: A CMM room can assist you in reducing waste and rework by automating your quality control procedures. This will improve the effectiveness of your production processes.

- Greater customer satisfaction: Offering high-quality goods can boost consumer contentment and loyalty, which can help you establish your brand and attract new clients.

- Competitive advantage: Using a CMM room to distinguish yourself from your rivals and get a competitive edge might help you show that you are dedicated to accuracy and quality control.

- If you are operating or producing parts for certain industries they will often want reassurance of the environment in which these parts are tested, calibrated and quality controlled. Having your CMM machine operating in the correct environment within a CMM Room will help demonstrate this.

Is a CMM the Same as a Close Control Room?

Although the terms “CMM room” and “close control room” are frequently used interchangeably, they can have different meanings. A temperature-controlled space called a close control room is made specifically to contain sensitive equipment or used as research and development space. like servers and computer systems.

While a CMM room offers a stable environment for exact measurements, a close control room offers a controlled setting to safeguard delicate equipment from temperature changes, humidity changes, and other environmental conditions that could possibly harm the equipment.

CMM rooms tend to operate constantly within a range of temperature and humidity control, whereas some of the close control rooms can be designed to your own requirements, with steady state tight temperature control and humidity levels or in a way that changes can be made within research spaces to mimic operating conditions.

Even though both CMM rooms and close control rooms offer a controlled environment, a CMM room’s main objective is to produce precise measurements, whereas a close control room’s main objective is to safeguard delicate equipment or ensure that humidity is kept low.

What Equipment is Needed for a CMM Room

For a CMM room to work effectively and deliver precise measurements, it needs a variety of specialised items of equipment. A Coordinate Measuring Machine (CMM), which is used to take exact measurements of components and products, serves as the most significant piece of equipment. Other tools that can be needed in a CMM room in addition to a CMM include:

- Specific climate control systems to maintain temperature and humidity levels (tight delivery of temperature and humidity control is unlikely to be achieved using conventional air conditioning systems)

- Design and delivery of air to the space taking into account air change rates, means of delivery of air flow and return to minimise any disruption to the CMM machine

- Lighting to provide proper illumination for measurements

- Power and data management systems to ensure that the equipment is powered and connected

- Workstations and storage solutions to accommodate your team and equipment

- Consideration of any air locks, or soak areas depending on the purpose of the room

It’s important to work with a company that specializes in CMM rooms to ensure that you have the right equipment and that it is installed and configured properly. By having the right equipment in place, you can ensure that your CMM room provides accurate measurements and meets your quality control needs.

Designing a Custom CMM Room For Your Business

The process of creating a unique CMM room for your company can be difficult and sophisticated. It necessitates meticulous planning and analysis of various aspects, such as the room’s dimensions and layout, the equipment you’ll be utilising, and the setting in which you’ll be working.

Working with a business that specialises in developing and constructing custom CMM rooms is essential if you want to make sure that your CMM room produces precise measurements and fulfils your quality management requirements.

Interested In Installing A CMM Room For Your Business?

There are several things to think about when installing a CMM room for your company, including the room’s size and layout, the tools you’ll need, and the surroundings in which you’ll work. To make sure you get the best solution for your organisation, it’s crucial to engage with a company that specialises in developing and constructing custom CMM rooms.

The controlled environment of a CMM room allows for accurate measurements and quality assurance. Businesses can increase the effectiveness of their quality assurance procedures, improve product quality, as well as achieve a competitive advantage by incorporating Coordinate Measuring Machines (CMMs).

TEK design and install state of the art CMM rooms for a range of businesses. All rooms are designed with your business in mind, ensuring that it is designed and installed exactly to your specification to meet all of your requirements.

Our rooms are bespoke to meet your exact requirements, taking into account your equipment, product, and the space available. We have designed and installed many of these throughout the UK in a variety of settings from Aerospace, Engineering to Research and healthcare

If you’re considering your options for installing a CMM room or enclosure in your organisation think about working with a company like TEK, who specialise in the design and installation of CMM rooms. Get in contact with our team today for more information.